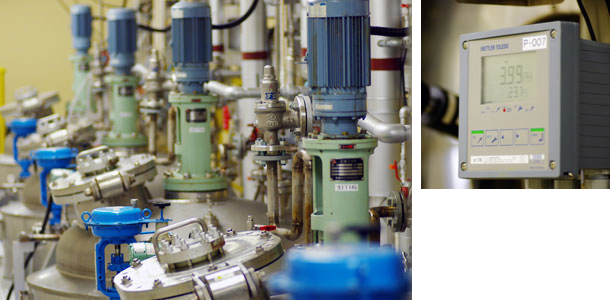

Strict quality control and careful production management are indispensable pillars of Daiwa’s manufacturing process. Our Tsukuba Plant operates to HACCP standards (Hazard Analysis Critical Control Point) and is certified to FSSC22000. The facility contains the latest equipment for beneficial microorganism cultivation to ensure high quality and excellent stability. And it exercises vigorous environmental control procedures, in full compliance with the strict standards of the local area in disposing of effluent. These continuous efforts ensure the manufacture of safe, reliable and efficacious products, while safeguarding the health of the planet.

|

|

▶ Takao Fukuda, General Manager ▶ Satoshi Kato, Manager, Quality Control Section and Development Section ▶ Takeo Yuhara, Assistant Manager, Manufacturing Section |

I was personally involved in the establishment of the Tsukuba plant from the initial stages, including its design and facility planning. This sophisticated plant is certified by FSSC22000 and has excellent equipment as well as a great management team. In regards to plant management, it is mandatory to establish and maintain an optimized manufacturing system to assure product stability and safety; therefore, we composed a control and management system required for HACCP, which is a certificate to ensure product safety. HACCP has contributed to better management of our plant, a hygienic environment, manufacturing efficiency, and stabilization of product quality, as just a few examples. Additionally, we have been certified with FSSC22000 (Food Safety System Certification), which provides a framework for effectively managing the organization's food safety responsibilities, since 2018. FSSC 22000 is fully recognized by the Global Food Safety Initiative (GFSI) and is based on existing ISO Standards.

After completion of the construction, I also managed the start-up of product facilities and the pilot plant. In terms of product development, I contributed to the development of a new material, Rice Kefiran, and conceived the plan to launch it as a novel product.

As Plant Manager, I will continuously try to improve the manufacturing system by reviewing manufacturing procedures and updating plant equipment in order to maintain product stability and safety.

Additionally, I am certain that we will continue efforts to develop more new and beneficial raw material, since our overall objective is to contribute to a better quality of life for our customers.

I am committed to quality control and manufacturing development at Tsukuba Plant.

Product safety has been given increasing attention in the functional food and food manufacturing industry. The Fukushima nuclear power plant accident has accelerated this trend. Safety must be a priority, regardless of such social environments, of course, and overseeing quality control is a critical position with a high level of responsibility.

At present, I put the largest emphasis on the analysis of radiation exposure. We actually receive many inquiries about this issue from our customers. We are making every possible effort to assure our customers of the high standards of safety that comes with our products, and that radiation is checked in every part of our products.

International transactions have expanded along with the growth of the company, especially when compared to many years ago when I joined the company. Requirements for product quality certificates differ slightly according to each nation, since each nation has its own culture and regulations. Nonetheless, the commonality is that product safety is critical in every nation. Although it can be demanding to prepare the various documents which meet their requirements, I feel it is worthwhile.

The main purpose of the manufacturing and development department is to improve the manufacturing process for existing products and to test the manufacturing process for ramping up manufacturing of new products. I find the fermentation technology that uses microbes to be the most unique advantage of Daiwa Pharmaceutical’s products.

I majored in microbiology at the university and feel the knowledge and skills which I acquired have greatly helped me carry out these duties. Microorganisms are easily influenced by the environment. Whenever instability of product quality is discovered, there must be a cause. Although one needs patience to determine the cause of a problem and find its solution, this process is fun for someone like me, who is strongly interested in microbiology.

About 11 years have passed since I first joined Daiwa Pharmaceutical. I feel that time has flown quickly, and now I am in charge of two important duties: quality control and manufacturing development. I always keep in mind that I have the responsibility of assuring product stability and safety and am determined to continuously manufacture more satisfactory products for our customers.

I belong to the Manufacturing Section in the Manufacturing Department and am committed to producing various culture solutions and semi-processed products. This is a challenging and worthwhile position for me, since it is the starting point for the whole manufacturing process. I expend great effort to ensure consistent product quality and reduced manufacturing costs, which is the ultimate goal for the manufacturing department.

Tsukuba Plant has expanded to increase the quality control process for both systems and facilities, which has been certified with FSSC22000. At present, I have increased my focus on stabilizing various parameters for each product. I am expected to continuously enhance the stability of product quality by carefully examining the dispersion of data in the case of a problem, analyze the cause and take appropriate measures to prevent it.

The fundamental requirements for our department are to meet customers’ expectations by manufacturing high quality products at a reasonable price and in a shorter period of time in order for it to be available on demand. I will continuously improve QCD (Quality, Cost, and Development), by resolving problems and overcoming challenges.